Compressed Gas Cylinder Safety

INTRODUCTION

WSU facilities use a variety of gases for many different activities. Compressed gas cylinders range from small lecture bottles to large cylinders with more than 200 cubic feet of gas. No matter the type of gas or type of gas cylinder, most gas cylinders have common hazards associated with their use and storage. Before using a compressed gas cylinder, individuals should become familiar with their general and specific hazards (chemical and physical). This fact sheet provides a summary of common gas cylinder hazards and best practices. For more detailed information, see the links in the Learn More section of this document.

This fact sheet is not intended to replace the Safety Data Sheet provided by the manufacturer.

HAZARDS

- Due to the high pressure within a gas cylinder, a cylinder rupture or valve damage will result in a rapid release of gas that can cause the cylinder to propel forcefully for a long distance, making them a potential rocket or fragmentation bomb that can penetrate through walls.

- Since many cylinders contain a gas that is not breathable air, the release of gas (slowly or quickly) can displace oxygen in the surroundings, creating an asphyxiation hazard.

- The gases themselves can be hazardous, including simple asphyxiant, toxic, corrosive, extreme cold, and flammable. See gas specific safety data sheets to understand the hazards.

- A compressed gas cylinder with a pressure gauge reading of 0 kPa or 0 psig is not completely empty. It still contains gas at atmospheric pressure and must be treated with the same safety precautions as a full cylinder.

- Many gas cylinders are large and very heavy, even when empty. A falling cylinder can crush feet, hands, or potentially the whole body.

BEST PRACTICES

Moving

Incidents and injuries commonly occur during handling or transportation. Follow these precautions to minimize the risk:

- Use appropriate personal protective equipment (PPE), including safety glasses, heavy-duty gloves and protective footwear, when disconnecting and moving gas cylinders.

- Handle cylinders with care and avoid dropping or hitting them against anything.

- Avoid lifting cylinders by their caps or guards or with magnetic slings.

- Securely install safety devices, such as valve caps/covers or guards, before transporting a cylinder.

- Transport gas cylinders with caps (valve covers) in place and tightly secured to a cart designed for gas cylinder transport. Use a helper if possible. Never carry, drag, roll, or “walk” cylinders or lecture bottles by hand.

- Where available, use the building’s freight elevator to transport gas cylinders between floors. Because of the reduced air circulation in elevators and asphyxiation risk of many gases, consider not riding on the elevator with the cylinder. Have another person meet the cylinder at the destination floor.

Using

- Consult Safety Data Sheets (SDS) for safety information on the gases you are using.

- All cylinders being used must have their contents and precautionary labeling clearly marked on their exteriors. Never rely on the color of the cylinder for identification. Color coding is not reliable because cylinder colors may vary depending upon the supplier.

- Always wear approved PPE including eye protection as recommended by the SDS.

- Inspect gas cylinders and regulators prior to use. Never use cylinders or regulators that are damaged or corroded.

- Before attaching the regulator, slightly open and then immediately close the valve to clear any debris that might be in the valve. Open cylinder valves with valve outlet away from you.

- For flammable gas cylinders, once the regulator is attached, do not open the valve more than 1 ½ turns, to ensure quick closing in case of an emergency.

- Discharge compressed gases using devices, such as pressure regulators, approved for the gas being used.

- Close the main cylinder valve as soon as it is no longer necessary to have it open.

- Before removing the regulator, close the cylinder valve and allow the remaining gas to release from the open regulator.

Using & Storing

- Limit the number of gas cylinders purchased and on-hand to what is immediately needed.

- Group cylinders by the type of gas and segregate by compatibility.

- Store cylinders in cool, dry, well-ventilated areas, away from incompatible materials and ignition sources.

- Store cylinders in a location free from vehicle traffic and away from excessive heat, exit doors, and electrical panels.

- Do not use or store in walk-in environmental rooms [walk-in refrigerators or freezers (i.e., cold rooms), or warm rooms]. Air in these rooms is 100% recirculated, which leads to an increased risk of asphyxiation.

- Secure cylinders with sturdy chains or straps to a wall or bench mount or use a cylinder rack or floor stand.

- The chain/strap must be secured tightly between 1/2 to 2/3 up the cylinder.

- Chain thickness should be at least ¼ inch diameter.

- Group cylinders by size to ensure all cylinders are properly secured.

- A rack designed for small cylinders may be the best method for securing them.

- Do not exceed the intended capacity of the securing system (e.g., bench mount designed for one gas cylinder should not be used for more than one gas cylinder).

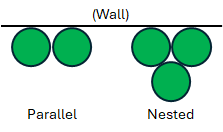

- Chains securely anchored to a wall must not have more than 2 parallel or 3 nested cylinders per chain.

- Wall-mounted anchors or brackets must be installed by FP&M.

- Gas distribution lines should be clearly labeled with the type of gas contained and the direction of flow.

- Store oxygen gas cylinders (full or empty) at least 20 feet from flammable gas cylinders or separate using a noncombustible barrier at least 5 feet high having a fire-resistance rating of at least one-half hour. Do not store oxygen gas cylinders near highly combustible material, especially oil and grease.

- Flammable compressed gas cylinders (e.g. Hydrogen, Acetylene) MUST be stored in areas away from open flames, other sources of ignition, and away from areas where electrical sparks are generated.

- Propane tanks/cylinders should not be used or stored in a WSU building basement. Consult with Enterprise Risk Management – Fire Safety Office at (313) 577-3110 on the proper use and storage of propane.

- Use warning signs in areas where cylinders are stored and used.

- Store empty and full cylinders separately. Mark empty cylinders “empty” or “MT”.

- Ensure valves are completely closed and cylinder caps are in place when not in use or connected for use.

PROPERLY SECURED GAS CYLINDERS

.

IMPROPERLY SECURED GAS CYLINDERS

DISPOSAL

- Lecture bottles should be collected in a hazardous chemical waste pail and disposed of by OEHS. Do not store lecture bottles of incompatible gases in the same pail. To request a waste pickup or a waste pail, submit a Chemical Waste Pick-Up and New Container Request Form.

- Empty, partially used (no longer needed), or damaged (rusted or structurally compromised) gas cylinders should be returned to their original vendor (e.g., Airgas) as soon as possible.

- If the compressed gas vendor is no longer in business, first contact WSU’s authorized compressed gas vendor to see if they are willing to take the gas cylinder. If they are not willing to take the gas cylinder, contact OEHS for disposal.

- Do not try to empty a partially used gas cylinder, as this may create an explosion and/or asphyxiation hazard.

LEARN MORE

- Airgas Compressed Gas Safety eBooks.

- OSHA Safety and Health Topics - Compressed Gas and Equipment

- MIOSHA PART 69, COMPRESSED GASES: ACETYLENE, HYDROGEN, OXYGEN, AND NITROUS OXIDE

- OSHA 29 CFR 1910.101 – Compressed gases (general requirements)

Gas cylinder suppliers can also help with identifying appropriate regulators, tubing, connections, and other accessories.